- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

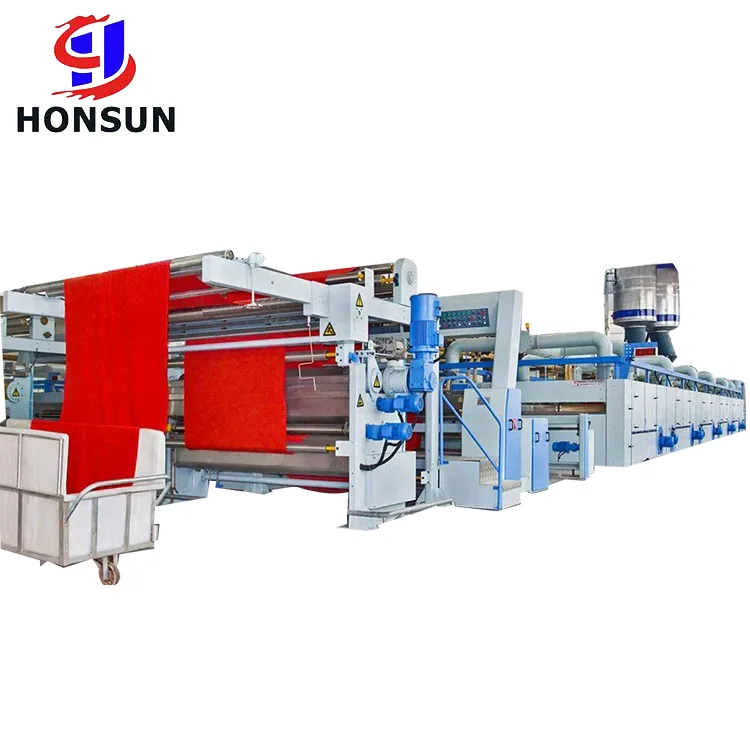

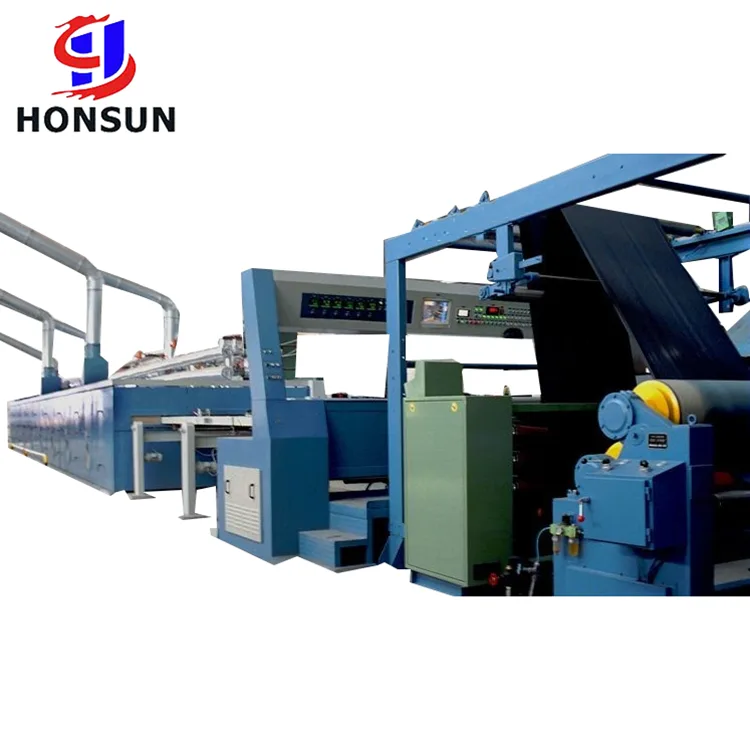

Stenter Machine Waste Heat Recovery Equipment

Maximize your energy efficiency with Hongshun's Stenter Machine Waste Heat Recovery Equipment, a high-quality solution that captures and reuses excess heat from your production process. As a leading China Stenter Machine Waste Heat Recovery Equipment factory, Hongshun offers competitive prices and reliable performance.

Send Inquiry

The waste heat recovery systems are designed to collect and repurpose the heat generated during the stentering process, significantly reducing energy waste and lowering utility costs. The Quality Stenter Machine Waste Heat Recovery Equipment from Hongshun ensures that every bit of energy is utilized effectively, enhancing both your environmental footprint and bottom line. With a comprehensive Price List available, you can easily find the right solution for your business. Whether you're looking to Wholesale Stenter Machine Waste Heat Recovery Equipment or need a Customized setup, our factory can deliver exactly what you need. Trust Hongshun as one of the top Stenter Machine Waste Heat Recovery Equipment Brands for innovative and sustainable solutions.

Product Features

1. Reasons for waste heat recovery: The exhaust gas temperature is high and energy is wasted.

1) The exhaust gas temperature of the stenter setting machine is 140-160°C, and the exhaust gas temperature of the burner is 200°C.

2) The high-temperature exhaust gas is directly discharged to the exhaust gas treatment equipment, resulting in a large amount of wasted heat.

3) Exhaust gas treatment usually requires energy-consuming methods such as spraying and condensation to cool down to 60-70°C, further increasing energy consumption.

2. Great potential for waste heat recovery:

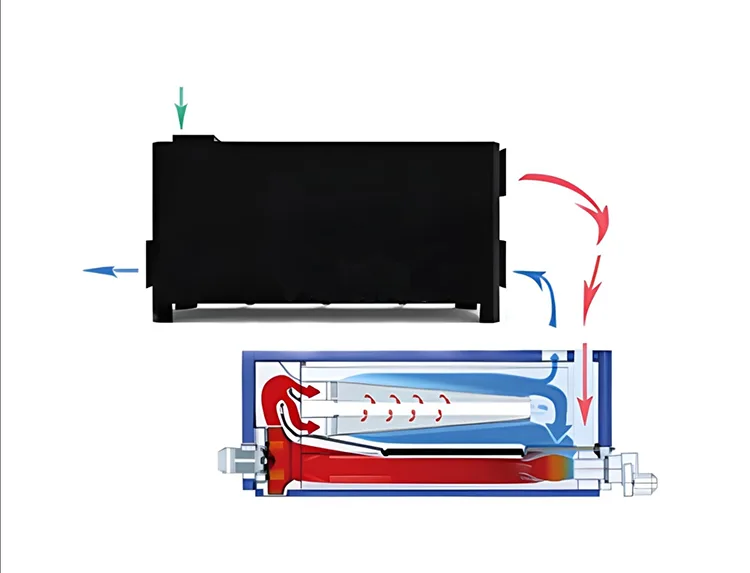

1) Using high-temperature exhaust gas to heat fresh air or normal-temperature water can significantly reduce energy waste.

2) The heated fresh air can be replenished into the stenter setting machine oven or other places where needed, and the hot water can be used for other purposes in the production process.

3. High-efficiency heat recovery system:

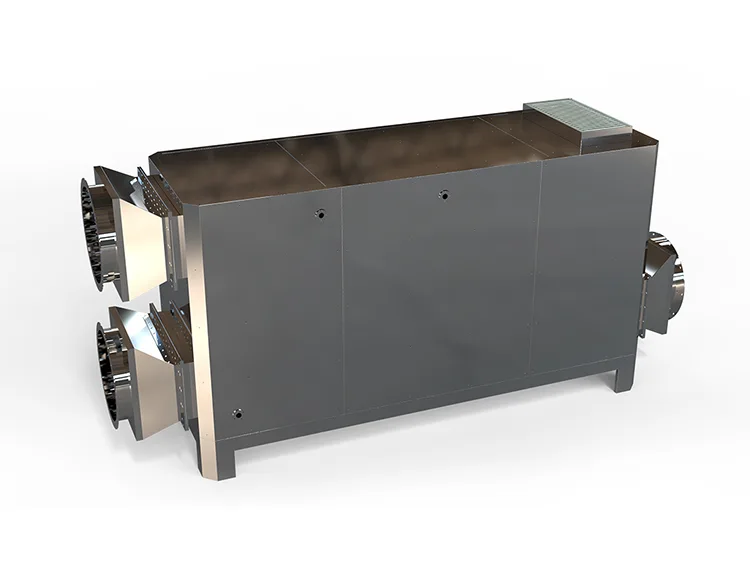

1) Our company has launched a high-efficiency heat recovery system for the air and gas of the shaping machine, which uses high-efficiency heat exchange materials and special design, with a heat exchange efficiency of 86%.

2) The system has a compact structure and low wind resistance, and does not affect the original exhaust system of the setting machine.

4. Intelligent safety design:

1) The system is equipped with touch screen and PLC control, which can automatically set fire extinguishing and cleaning functions according to working conditions.

2) Specially strengthened safety measures prevent fire risks caused by flammable substances such as lint and chemical oils in high-temperature exhaust gas, ensuring long-term stable operation.