- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

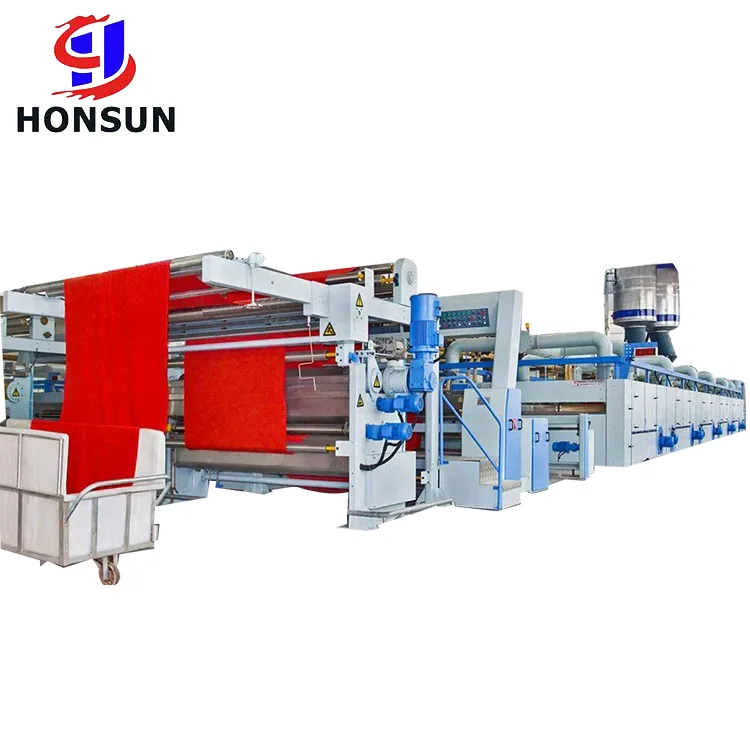

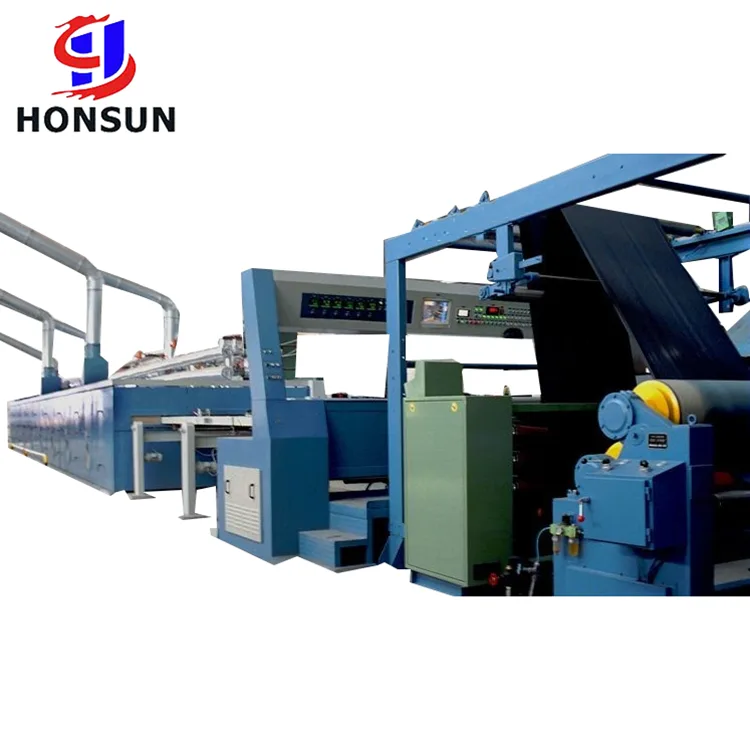

Stenter Machine Waste Gas Treatment Equipment

Discover the Hongshun Stenter Machine Waste Gas Treatment Equipment, an essential solution for textile processors seeking to enhance environmental compliance and operational efficiency. As a leading China Stenter Machine Waste Gas Treatment Equipment supplier, Hongshun offers advanced technology with a 1 Year Warranty, ensuring reliable performance.

Send Inquiry

Our Stenter Machine waste gas treatment equipment is designed to effectively capture and treat harmful emissions from stenter machines, providing a cleaner and safer working environment. The system features multiple stages of filtration and purification, reducing pollutants to meet stringent environmental standards. When you Buy Stenter Machine Waste Gas Treatment Equipment from Hongshun, you invest in a product that not only protects your workforce but also enhances your brand's sustainability. Whether you're looking for Wholesale Stenter Machine Waste Gas Treatment Equipment or need a Customized solution, our factory can meet your specific needs. Join the ranks of satisfied customers who trust Hongshun as one of the top Stenter Machine Waste Gas Treatment Equipment Brands

Work Process Flow

The First Treatment Stage (Spray Humidification Treatment):

High-temperature oil fume waste gas enters this stage through the flue and makes full contact with high-pressure water mist. This can wash away large oil fumes, particulate matter and achieve preliminary cooling.

The Second Treatment Stage (Filtration and Condensation Stage):

In this stage, the flue gas undergoes multiple filtrations and the action of condensers to further filter and reduce the temperature so that it can meet the state and temperature requirements suitable for high-voltage electrostatic work.

The Third Treatment Stage (Two-stage Electrostatic Treatment):

High-voltage electrostatic adsorption is used for dust and oil removal. Specifically, electrons emitted from the cathode and negative ions generated by the collision of electrons with air molecules capture oil fume and oil mist particles, making the particles charged. Then, with the action of the electric field, the charged particles are adsorbed by the anode, thus achieving the purpose of purification.

The Fourth Treatment Stage (Deodorization Device):

It is used to separate the unpleasant odors in the flue gas.

The Fifth Treatment Box (High-voltage Electrostatic Centralized Purification Box):

It conducts in-depth purification of the flue gas, and then enables the flue gas to be discharged up to the standard.

Details

Feature 1: Automatic Operation

Both of them operate automatically. They can carry out their work according to preset programs, automatically monitor and adjust relevant parameters without the need for frequent human intervention, which is labor-saving and efficient.

Feature 2: Targeted Treatment

The automatic industrial waste gas treatment device is designed to deal with the components of industrial waste gas, while the automatic cleaning device for oil fume waste gas is designed to handle the characteristics of oil fume. Each has appropriate processes to effectively treat the corresponding waste gas and achieve good purification effects.