- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

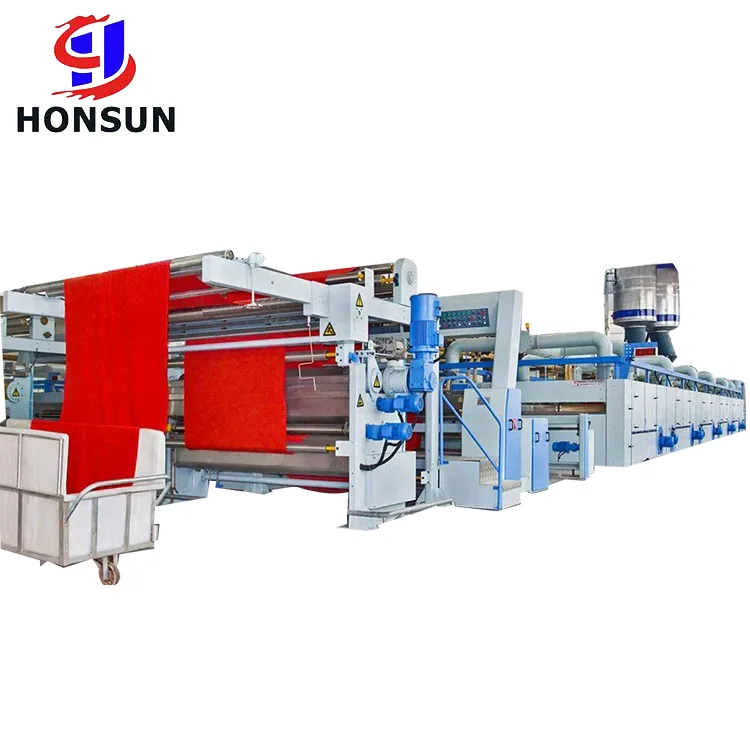

Stenter Machine Energy Saving Transformation

Transform your textile production with Hongshun's Stenter Machine Energy Saving Transformation, a cutting-edge solution for reducing energy consumption and lowering operating costs. As a trusted China Stenter Machine Energy Saving Transformation manufacturer, Hongshun provides advanced, cost-effective upgrades that deliver significant savings.

Send Inquiry

This Stenter Machine energy saving transformation kits are designed to retrofit existing stenter machines, optimizing their performance while minimizing energy use. By integrating smart control systems and efficient motors, we ensure that your machines operate at peak efficiency, reducing electricity bills and improving overall productivity. Cheap yet effective, these upgrades are perfect for manufacturers looking to modernize their facilities without breaking the bank. Whether you're seeking Wholesale Stenter Machine Energy Saving Transformation solutions or need a detailed Quotation, Hongshun is your go-to choice. Our experienced team will help you customize the perfect package to fit your unique requirements. Choose Hongshun for Advanced Stenter Machine Energy Saving Transformation and experience the benefits of a greener, more efficient operation.

System design:

1. Heat exchanger:

Adopt high-efficiency aluminum fin exchanger, with sufficient heat dissipation area and can meet the original installation position.

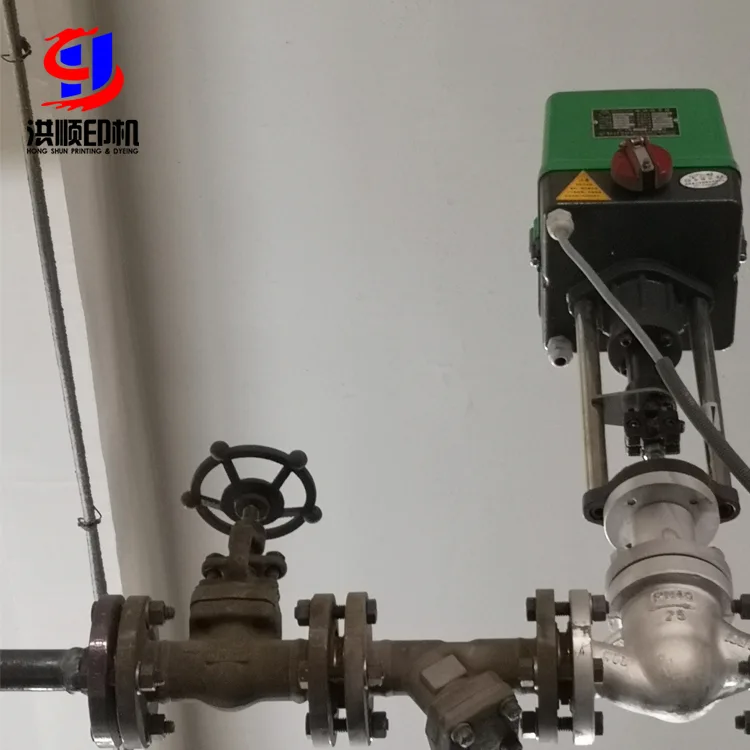

2. Analog control valve:

Adopt pneumatic or electric analog input, stable temperature control.

3. Temperature control system:

Adopt patented regulating steam trap designed by our company

4. Flash recovery system:

Unique steam drainage method and accurate calculation of steam drainage volume reduce steam consumption to nearly theoretical design data.

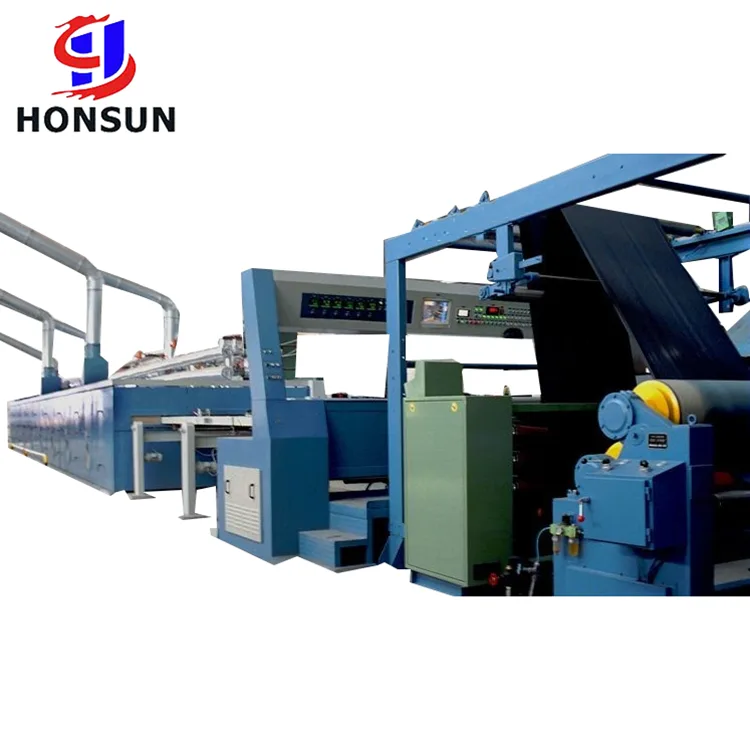

5. Pipeline system is designed according to high standards:

Safe, economical, beautiful and practical.

Details

Key points of energy-saving transformation:

1. Steam requirements:

Use medium-temperature medium-pressure steam produced by boilers, and reach a steam supply pressure of 0.7-3.8MPa and a temperature of 260-350℃(superheated steam) after temperature and pressure reduction.

2. Temperature control:

The steam inlet valve of each box is changed to "pneumatic or electric analog regulating valve", and a PLC automatic temperature control system is configured to ensure stable and accurate temperature and save steam.

3. Steam consumption metering:

According to customer needs, a flow meter can be installed on the main steam pipe of each setting machine to facilitate production monitoring and assessment.

4. Waste heat recovery:

The flash steam recovery system is used to connect the flash steam to the dyeing plant heat network, which can recover 15%-20% of the steam; the condensed water generated after setting is separated and recovered for boiler or dyeing machine water.

5. Energy consumption:

The actual energy consumption is about 0.8 tons of steam, which is far lower than the industry average. The maximum process temperature of the setting machine can reach 220℃, which is suitable for fabrics with a maximum weight of 550g.