- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the advantages of using a cylindrical knitted fabric dryer?

2025-05-12

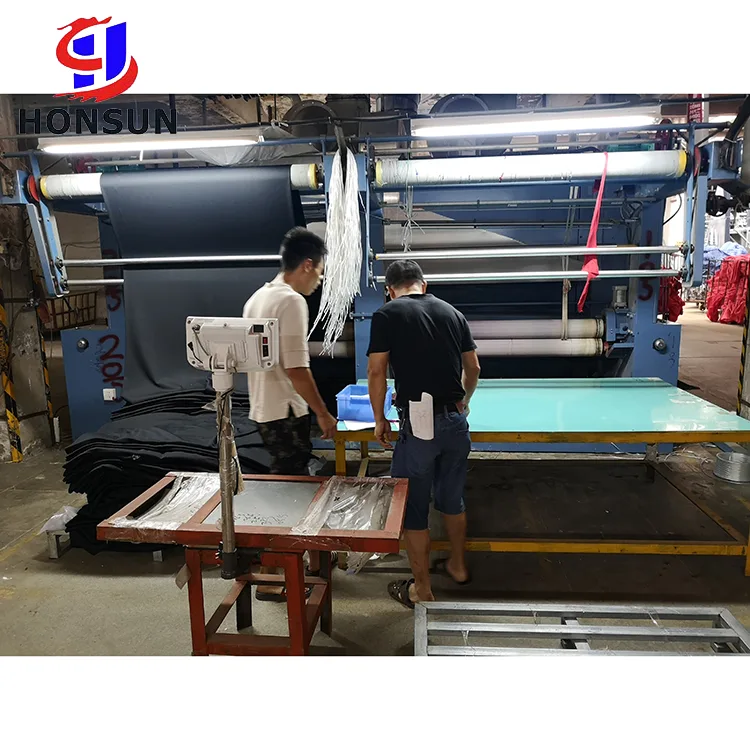

As a key equipment in the textile finishing process, the cylindrical knitted fabric dryer is widely used in the drying and processing of flexible textiles such as knitted fabrics, ready-made clothes, and towels. Its core function is to evenly dry the knitted fabrics wound on the cylindrical mold through the synergy of hot air circulation and mechanical transmission.

In the clothing manufacturing industry, the cylindrical knitted fabric dryer can effectively eliminate the residual moisture of the fabric during the dyeing and washing process, while maintaining the elasticity and dimensional stability of the fabric through the temperature control system, avoiding the fiber hardening or deformation caused by traditional drying. The intelligent sensor configured inside the equipment can monitor the temperature and humidity changes in the drum in real time, and automatically adjust the drying parameters according to the weight and composition differences of the fabric. This precise control is particularly suitable for processing blended knitted fabrics containing highly elastic fibers such as spandex.

Compared with flat-plate drying equipment, the three-dimensional surround heating mode of the cylindrical knitted fabric dryer can make the hot air penetrate the fabric layer more fully, significantly improving the drying efficiency of thick terry or velvet fabrics. In the field of industrial washing, this equipment is also used in the rapid drying and sterilization process of hotel linens and medical textiles. Its high-temperature hot air can not only evaporate moisture, but also destroy the microbial structure to achieve hygiene standards.

With the increasing demand for energy conservation and emission reduction in the textile industry, the new cylindrical knitted fabric dryer reduces unit energy consumption by about 30% through waste heat recovery system and variable frequency drive technology, while ensuring the fluffy and soft fabric and reducing carbon footprint. This equipment has become an important technical support for balancing production efficiency and product quality in the modern textile industry chain.